The prior inspection of all machinery critical to industries is a priority to avoid personal accidents, material damage and production losses.

In industries, especially those that operate critical machinery, safety and efficient performance are critical. To ensure optimal operation, it is vital to perform pre-operation inspections of all critical machinery. These inspections, which may seem like an extra, routine step, play a crucial role in preventing accidents, minimizing risks and properly maintaining equipment. In this article, we will explore the importance of carrying out these inspections and how they contribute to the safety and success of industrial operations.

The pre-operation inspection of critical machinery is a comprehensive process that involves carefully reviewing and evaluating each component and function of the equipment before putting it into operation. This process makes it possible to identify possible failures, wear or deficiencies that could cause accidents or interruptions in production. In addition, pre-inspections help pinpoint any need for maintenance or repair, helping to extend the life of machinery and minimize long-term operating costs.

Safety is one of the main benefits of performing pre-operation inspections. By identifying and correcting any potential problems, the chances of serious or even fatal workplace accidents are reduced. The inspection also ensures that safety standards set by authorities and industry standards are met. This not only protects workers, but also prevents property damage and maintains the company's reputation.

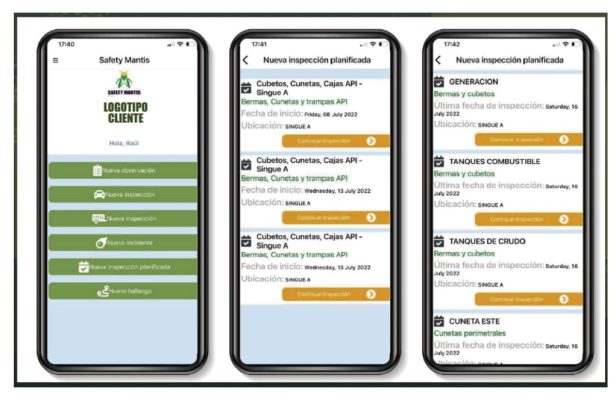

At SafetyMantis, Software for Management and Control in Industrial Safety and Occupational Health, we have a module that precisely allows us to carry out all types of machinery inspections, report findings or sub-standard or risk conditions, manage corrective actions, assigning dates limit, responsible parties and means of verification. For more information visit: https://www.safetymantis.com/reportes-inspecciones-de-campo/